Ballast Water Treatment System Installation

How does a Ballast Water Treatment System (BWTS) work?

Invasive Aquatic Species in ship’s ballast water is one of the biggest problems faced by the shipping industry. Posing a great threat to the marine ecosystem, these aquatic species has led to an increase in bio-invasion at an alarming rate. Under IMO’s “International Convention for the Control and Management of Ship’s Ballast Water and Sediments”, implementation of ballast water management plan and ballast water treatment system on board ships has thus become important.

● ● ● In order to ensure their ships comply with the rules and regulations set by IMO regarding Ballast Water Management, several shipping operators have started implementing ballast water treatment systems on their ships.

● ● ● A variety of technologies are available in the market for treating ballast water on ships. However, constraints such as availability of space, cost of implementation, and level of environmental friendliness play an important role in usage of a particular type of ballast water treatment system.

● ● ● A number of factors are taken into account for choosing a ballast water treatment system for a ship. Some of the main factors taken into consideration are –

● Effectiveness on ballast water organisms

● Environment-friendliness

● Safety of the crew

● Cost effectiveness

● Ease of installation and operation

● Space availability on board

The main types of ongoing projects for ballast water treatment by Navalista are Full Flow

Electrolytic

System and

Ultra-Violet (UV) Treatment Method. Our company recommends (but is not limited to) the use of

these

systems for ballast water treatment.

The most popular BWTS types that NAVALISTA develops installation design for:

...let's talk about Full Flow Electrolytic System!

What is abundantly clear is that Filter UV systems cannot operate

in

challenging waters without imposing constraints on ship cargo operations. Such UV BWTS, cannot

apply a

backup plan to manipulate the water quality to meet its SDLs. This means that if the targeted

UVI is

not met following the maximum allowed flow reduction - or the UVT mentioned in system Type

Approval is

not met - then the system control cannot accommodate such a challenge and will shut-down.

Electro-chlorination systems do not have this major disadvantage. These systems can increase the

uptake water salinity by adding sea water or increasing the water temperature with a heater in

the

case of side-stream electrolysis BWTS. Modern systems achieves the former with the use of

intelligent controls and without the need of heating, since it can work down to –2 0C of

electrolyte

feed temperature.

● ● ●

● ● ●

BALLASTING

During ballasting, the water goes through the filter, where

organisms

and sediment (with a diameter larger than 40 microns) are separated and further discharged

overboard.

● ● ● The filtered water enters the Electrolytic Cell. From the chlorides of the water, free chlorine is produced through the electrolysis process at a very low concentration (around 4-6 mg/L). The treated water then, enters the ballast tanks.

● ● ● The filtered water enters the Electrolytic Cell. From the chlorides of the water, free chlorine is produced through the electrolysis process at a very low concentration (around 4-6 mg/L). The treated water then, enters the ballast tanks.

DE-BALLASTING

It is a common practice for Bulk Carriers to use different

ballasting

and

de-ballasting rates. This is caused by cargo terminal loading and unloading

rates. It is frequently the case that de-ballasting needs to be conducted twice as

fast as ballasting. A good example is Australia where de-ballasting must take

place in less than 18hrs for a Capesize Bulk Carrier ( > 50,000m3 of ballast

water).

● ● ● During de-ballasting, the system will only monitor the residual oxidants and will further intervene if necessary. The main stages of the system (filtration and disinfection) are bypassed.

● ● ● A Total Residual Oxidants (TRO) sensor samples the residual chlorine at the discharge line. If it is greater than 0.1 mg/L, a dosing pump is operated for the dosage of neutralizing agent (Sodium Bisulfite). Successful neutralization of free chlorine is confirmed by a second TRO sensor, installed at the far end point of the ballast discharge line.

⚊ ⚊ ⚊

● ● ● During de-ballasting, the system will only monitor the residual oxidants and will further intervene if necessary. The main stages of the system (filtration and disinfection) are bypassed.

● ● ● A Total Residual Oxidants (TRO) sensor samples the residual chlorine at the discharge line. If it is greater than 0.1 mg/L, a dosing pump is operated for the dosage of neutralizing agent (Sodium Bisulfite). Successful neutralization of free chlorine is confirmed by a second TRO sensor, installed at the far end point of the ballast discharge line.

...let's talk about Ultra-Violet (UV) Treatment Method!

Ultraviolet ballast water treatment method consists of UV lamps

which

surround a chamber through which the ballast water is allowed to pass. The UV lamps (Amalgam

lamps)

produce ultraviolet rays which acts on the DNA of the organisms and make them harmless and

prevent

their reproduction. This method has been successfully used globally for water filtration purpose

and

is effective against a broad range of organisms.

● ● ● The special light sterilizes the water in the ballast water tanks. In the UVC range, a wavelength of 254 nanometers destroys the DNA of the bacteria and pathogens making them inactive, and thus prevents them from reproducing.

● ● ●

UV disinfection is effective at wavelengths from 200 nm to 300 nm.

The

UVC radiation emitted has a strong bactericidal effect. It is absorbed by the DNA, destroys its

structure and inactivates living cells. Microorganisms such as viruses, bacteria, yeasts and

fungi are

rendered harmless within seconds by UV radiation. If the irradiance is high enough, UV

disinfection is

a reliable and environmentally-friendly method eliminating the need for chemicals. Moreover, the

microorganisms cannot become resistant to UV radiation.

● ● ●

UV disinfection is effective at wavelengths from 200 nm to 300 nm.

The

UVC radiation emitted has a strong bactericidal effect. It is absorbed by the DNA, destroys its

structure and inactivates living cells. Microorganisms such as viruses, bacteria, yeasts and

fungi are

rendered harmless within seconds by UV radiation. If the irradiance is high enough, UV

disinfection is

a reliable and environmentally-friendly method eliminating the need for chemicals. Moreover, the

microorganisms cannot become resistant to UV radiation.

The standards for clean ballast water defined by the IMO, helps stem the introduction of invasive aquatic organisms. With the 2017 ratification of IMO regulations, environmentally compatible treatment systems for ballast water will soon be mandatory on all maritime vessels operating in international waters that discharge ballast water.

● ● ● Your advantages with UV light

● Fast, efficient and economical technology

● Simple to handle with low maintenance

● Eco-friendly, safe and chemical free process

● No transport, storage and handling of dangerous goods

● No environmental impact

● ● ● The special light sterilizes the water in the ballast water tanks. In the UVC range, a wavelength of 254 nanometers destroys the DNA of the bacteria and pathogens making them inactive, and thus prevents them from reproducing.

The standards for clean ballast water defined by the IMO, helps stem the introduction of invasive aquatic organisms. With the 2017 ratification of IMO regulations, environmentally compatible treatment systems for ballast water will soon be mandatory on all maritime vessels operating in international waters that discharge ballast water.

● ● ● Your advantages with UV light

● Fast, efficient and economical technology

● Simple to handle with low maintenance

● Eco-friendly, safe and chemical free process

● No transport, storage and handling of dangerous goods

● No environmental impact

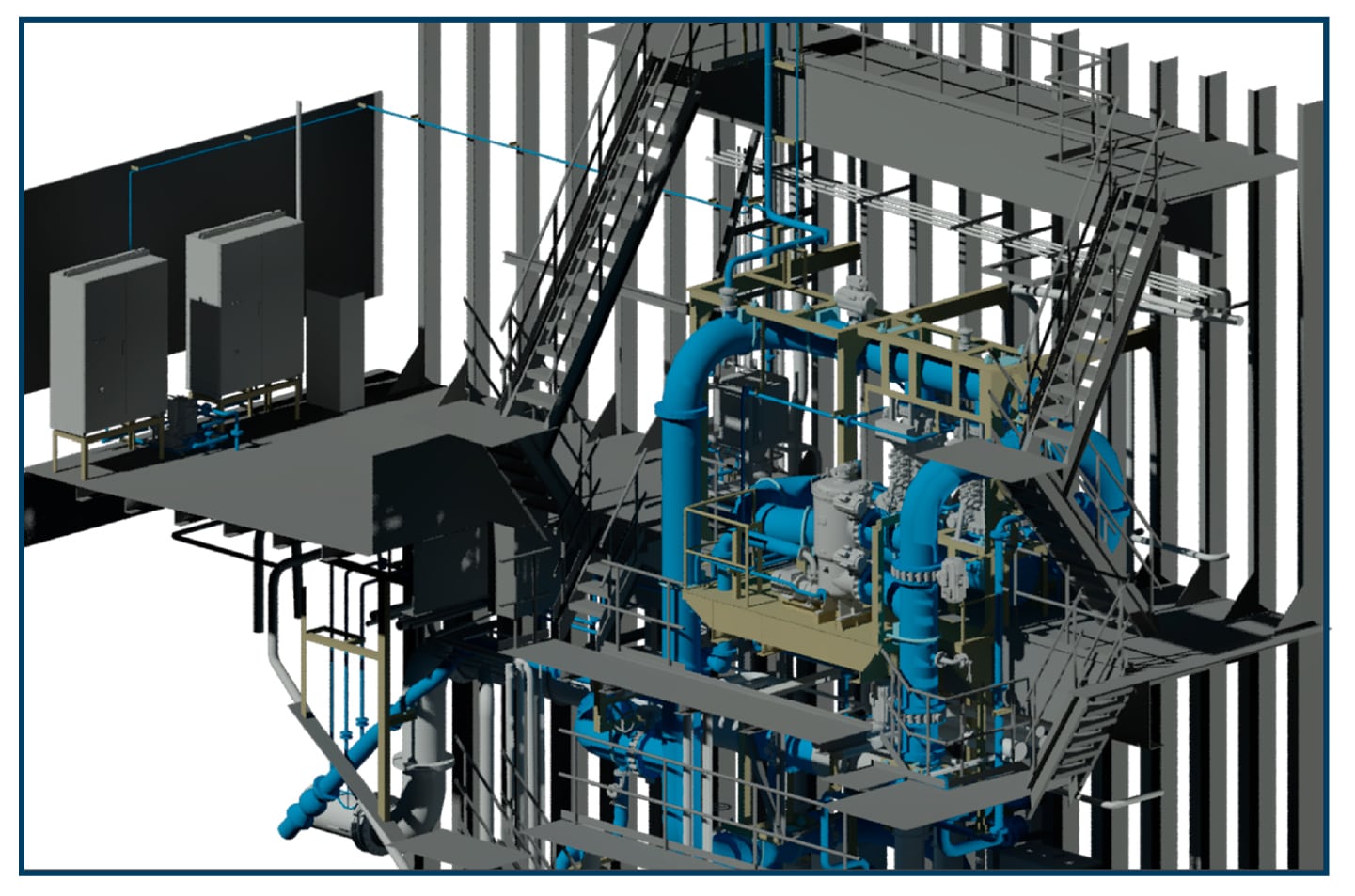

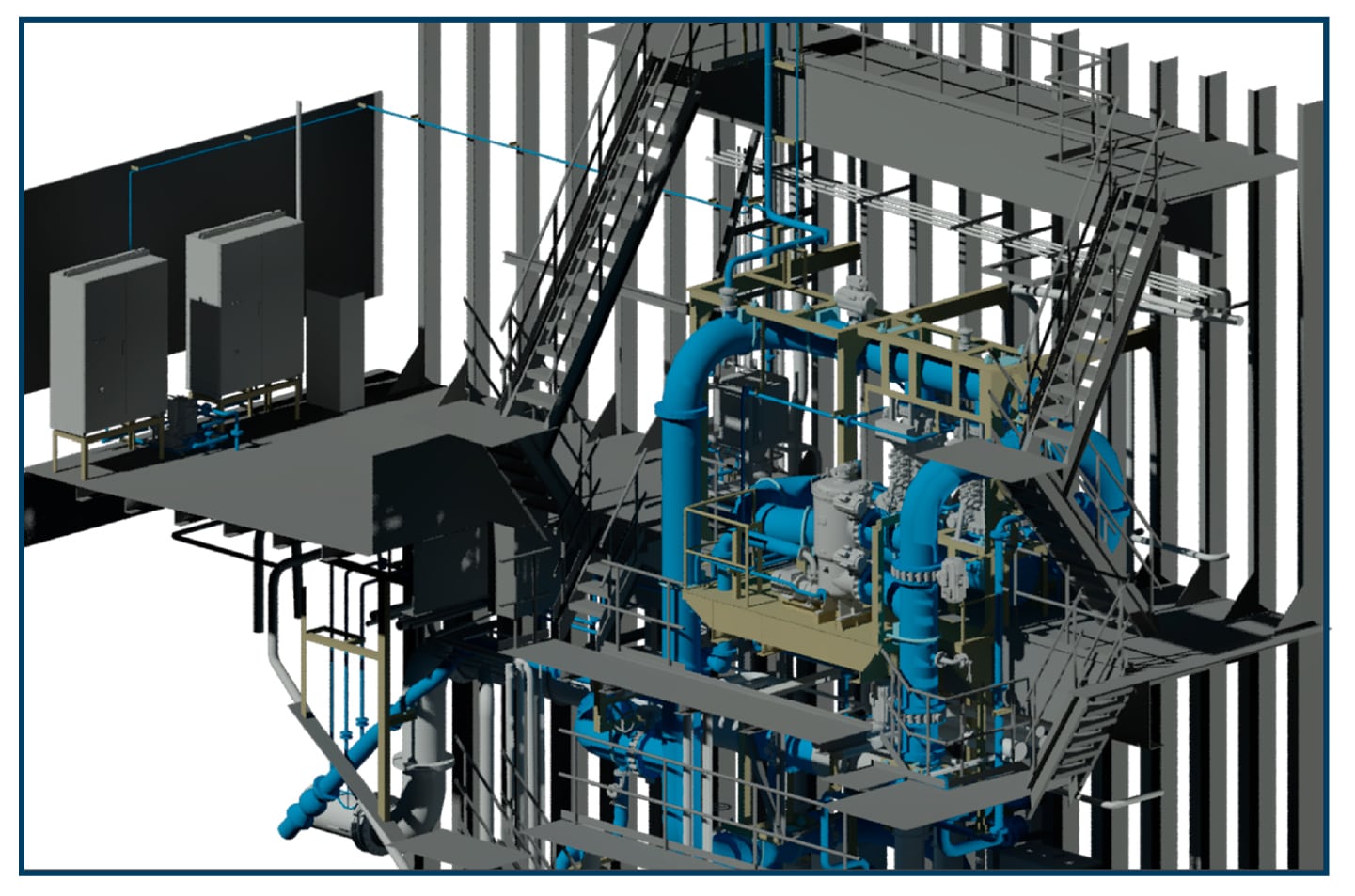

Navalista has developed a large number of projects

using

these technologies and has excellent reviews from our partners. We are also ready to carry

out any

projects on other ballast water treatment technologies.

examples

obvious advantages